The Plastics Debate – The Full Picture

Plastic is the focus of much negative attention at the moment and is being demonised for it’s damaging effects on the environment.

In the rush to put all the blame on plastic however, we should be careful about coming up with simple solutions to complex problems and it is important for people to understand that ‘plastic free’ does not necessarily mean ‘better for the environment’.

In a number of situations switching to alternative materials can lead to an increased environmental impact, not less.

Plastic will – and should – continue to play a vital role in all our lives. That may sound surprising, but here we explain why.

The enemy is not plastic, it is plastic waste

First things first. Along with all waste, plastics waste is certainly a big problem that needs to be urgently improved in order to protect our environment.

Plastics recycling facilities are already widely available and it is important that just like all waste, when no longer needed, plastics are placed in the appropriate recycling stream. Clearly if not properly disposed of there is the risk of plastic finding its way into the natural environment, where it can cause well-documented harm. Responsible disposal to facilitate recycling is an important step in reducing environmental impact.

All plastics can be recycled but there are currently technical barriers to recycling some types on an industrial scale, although work is being done around the world to overcome these. The plastics industry is working with the UK government to achieve the common goal of simplifying what is collected for recycling across the UK to make it easier for people.

Why do we need single-use plastic anyway?

Many packaging materials are only used once before being recycled or sent to landfill. However, plastic, rather than other materials, is typically attached to the term ‘single use’ in the media. In an ideal world, plastic would not be thought of in this way because it would always be recycled into another product.

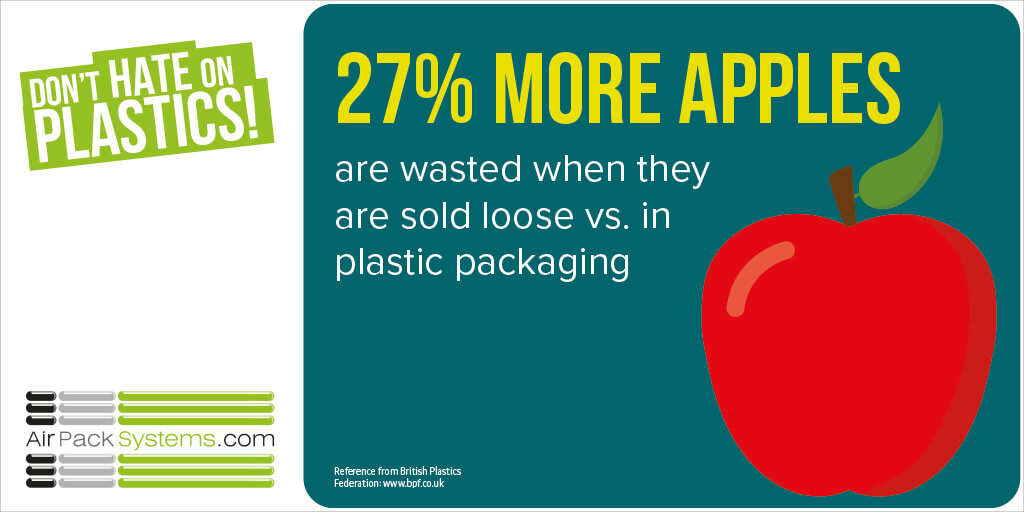

When food or other products are packaged in plastic, they are protected and in the case of fresh goods, they remain fresher for longer. Keeping food from spoiling reduces food waste which helps reduce the strain in the planet’s resources and keeps costs down. This is partly why pre-packaged goods are often cheaper than loose goods. Inflatable plastic packaging is one of the most effective methods for protecting fragile items in transit, with significantly reduced levels of damage, with rates as low as 0.04% breakages for shipments achieved by customers over a period of an entire year. That’s a significant reduction in wasteful replacements, returns and replacement logistics,

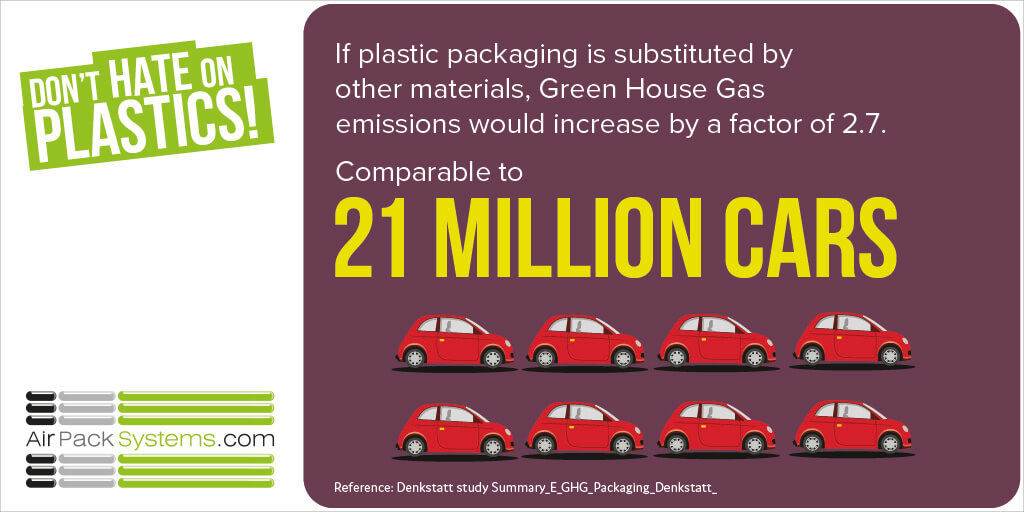

Switching to alternative materials may be worse for the environment, not better

Whilst plastic is currently under a lot of scrutiny, switching to paper or cardboard and other alternatives is not the simple green solution some may think. Let’s take a look at a comparison of what’s involved in the manufacture and recycling of plastic and paper.

Manufacturing

- The overall energy required to produce a paper bag is between four to fives more than a plastic bag

- Both production processes require water, but paper production is a particularly water intensive process, using approximately 15 times more water

- Paper bag production produces 70% more pollution than plastic bags

- Paper manufacturing generates 80% more greenhouse gas emissions than plastic bags

When it comes to protective packaging, there are a number of other environmental benefits for plastic over paper.

Lower Weight

The weight of any packaging materials will directly impact the amount of energy required to transport the packaging materials themselves and also the pack of finished goods to the retailer or end-user. Switching to a lighter weight material can positively impact your carbon footprint. Once inflated, inflatable bags consist of only 2% plastic and 98% air – so, that’s pretty much as light as air!

Less Space & Logistics Resource Needed

Deflated bags take up much less space than paper and board based protective packaging (for example there are an average of 10,000 AirPack deflated bags stored on just one euro pallet), meaning significantly less vehicles are required to transport large quantities and much less storage space is required, all helping to reduce CO2 emissions and carbon footprint.

Better Protection – Reduced Waste & Cost

Inflatable plastic packaging is one of the most effective methods for protecting fragile items in transit, with significantly reduced levels of damage, with rates as low as 0.04% breakages for shipments achieved by customers over a period of an entire year. That’s a significant reduction in wasteful replacements, returns and replacement logistics, costs and delays.

Re-Use

Plastic is more durable than paper so is more suitable for being reused multiple times. AirPacks are 100% reusable and can remain inflated for up to 2 years.

AirPack inflatable bags – Recycling and Biodegradable Options

Recycling

All AirPack inflatable bags are made from PET LDPE 4 material, which is 100% recyclable.

LDPE plastics are beginning to be accepted through kerbside recycling schemes, but there is still a way to go in improving the understanding of which types of plastic can be recycled, such as yoghurt pots and plastic trays, and the more widespread availability of recycling facilities.

OXO-Biodegradable Plastic

OXO-biodegradable plastic contains a catalyst to significantly speed up the biodegradation process and degrades in the presence of oxygen. When disposed of in landfill OXO biodegradable plastic will break down over time and will be converted into CO2, H2O and biomass.

AirPack OXO-biodegradable bags have been tested by the SP Technical Research Institute of Sweden (“SP”) who performed SP Method SPCR 141 Appendix 4 “Polymeric Waste degradable by abiotic and subsequent biological degradation (A + B Degradation)- Requirements and test Methods.” SP concluded that the test material fulfils all the requirements of SPCR 141 appendix 4, which is in accordance with ASTM D6954.

A small proportion of the bag material is made from nylon to improve performance, which is not biodegradable.

See the bigger picture

It’s certainly true that we all need to keep working hard to improve the way we manufacture, use, re-use, recycle and ultimately dispose of packaging materials, whatever they’re made of, and the problem of our polluted oceans needs urgent attention. More resources and education are surely needed around the responsible use and disposal of our waste, and no doubt increased research and innovation into plastics recycling will be part of the answer.

But we also need to be careful not to oversimplify our response to one environmental problem only to end up with an even bigger one to deal with.

For more information please contact AirPack Systems on +1256 300 480. More information on understanding the debate about plastic is also available from the British Plastics Federation – follow the link to understand the debate about plastic.